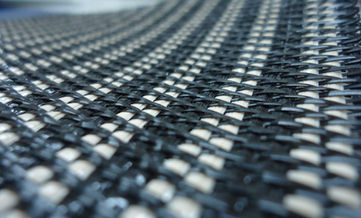

Geotekstil Tenun merupakan struktur tekstil planar yang dihasilkan dengan cara menyilangkan dua atau lebih rangkaian elemen seperti benang, serat, roving, atau filamen, yang mana elemen-elemen tersebut saling melewati satu sama lain untuk membentuk struktur yang stabil.

Sifat utama Geotekstil woven adalah kekuatannya dan karena sifatnya tersebut, Geotekstil woven dikelompokkan menjadi:

• Geotekstil Tenun Kekuatan Tinggi

• Geotekstil Tenun Kekuatan Rendah

WOVEN

GEOTEXTILE

Geo-Reinfox*

Geo-Reinfox* adalah Geotekstil anyaman yang terbuat dari polimer termoplastik yang diproses secara khusus untuk menghasilkan kekuatan tarik tinggi. Penambahan stabilisator UV memberikan Geo-Reinfox* ketahanan yang dibutuhkan selama masa konstruksi. Geo-Reinfox* telah digunakan selama puluhan tahun di Indonesia dalam berbagai aplikasi seperti konstruksi jalan, perkuatan lereng dan dinding, perkuatan pondasi, rel kereta api, dll.

Mirafi® PET

Geotekstil Mirafi® PET diproduksi menggunakan filamen poliester berkekuatan tinggi untuk menghasilkan kekuatan tarik tinggi pada ekstensi kerja rendah dengan creep minimal selama masa pakai desain hingga 120 tahun. Fungsi utamanya adalah perkuatan dengan fungsi pemisahan sebagai fungsi sekunder dalam banyak kasus. Kekuatan tarik berkisar antara 100 kN/m hingga 1.600 kN/m.

Mirafi® HPa

Geotekstil Mirafi® HPa menyediakan semua fungsi yang relevan untuk jalan dan platform penyangga beban lainnya yang dibangun di atas tanah dasar lunak. Mirafi® HPa menawarkan mobilisasi ketahanan tarik untuk manfaat perkuatan pada regangan kerja rendah sebesar 2%, aliran air yang tinggi untuk pembuangan tekanan pori berlebih dengan cepat, dan koefisien interaksi yang unggul untuk membatasi penyebaran agregat secara lateral pada antarmuka geotekstil dan lapisan agregat struktural.

Mirafi® HP and PP

Mirafi® HP dan PP adalah Geotekstil anyaman yang terbuat dari filamen polipropilena fibrilasi. Geotekstil Mirafi® HP dan PP menggabungkan kekuatan tinggi, permeabilitas tinggi, dan daya tahan yang sangat baik untuk digunakan dalam berbagai solusi rekayasa. Mirafi® HP memiliki rentang kekuatan tarik 35 hingga 105 kN/m, sementara Mirafi® PP memiliki rentang kekuatan tarik 100 kN/m hingga 200 kN/m.

Mirafi® FW

Geotekstil Mirafi® FW adalah jenis anyaman monofilamen, terbuat dari polipropilena, diproduksi menggunakan teknologi dan proses serat yang sangat terspesialisasi untuk menghasilkan sifat mekanis dan hidraulik unik yang tidak mungkin dicapai dengan Geotekstil standar. Geotekstil Mirafi® FW, dengan struktur sederhana dan terbuka, menawarkan permeabilitas tinggi tanpa ruang pori yang rumit untuk menjebak partikel.